1lb 2.85mm Taulman3D Alloy 910

[10442]

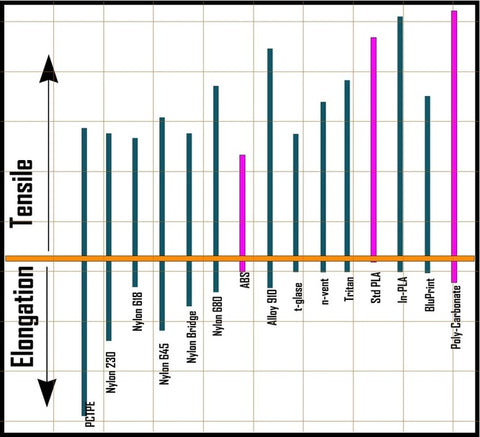

Alloy 910 is a measurable advancement in 3D Printing materials technology from taulman3D. taulman Alloy 910 is the combined effort of chemical companies, extrusion manufactures and taulman3D to specifically develop a single material to meet as many high performance 3D Printing needs as possible. With a combined tensile strength higher than the strongest co-polyesters, the durability of Nylons, a shrinkage factor that rivals our t-glase, a vast range of chemical resistance and a 95C working range, you now have one solution easily printable at 245C.

NOTE: Alloy 910 is the only Nylon based polymer that makes support removal easier than most using ABS

Specifications:

- Tensile Strength = 8,100PSI +

- Modulus PSI = 72,932

- Max Elongation at break = 31%

- Print Temperature = 245C

- Nozzle size = Any - There are no particulates or additives in Alloy 910

- Tg = 90C

- Print Bed: Cold = BuildTak with coat of PVA, Hot = Glass heated to 45C with coat of PVA

- (PVA is 50% water and 50% "Elmers Glue All")

- Shrinkage = 0.0031 in/in

- Transmission = 50%

- Color = Subtle Amber - May be dyed with acid based dyes

- Material specifications available at: http://www.taulman3d.com/alloy-910-spec.html

NOTE: Orders placed after 12 pm CT will not ship out until the following business day.

re:3D-specific E3D Hot End necessary for printing.

Quote valid for 30 days. Payment to be made in full in advance in order for product to ship. Refused Gigabot shipments will be charged return shipping and a $1000 restocking fee. Orders paid with a credit card or PayPal will be charged a 3% processing fee. Duty & tax are obligation of buyer. If this transaction involves an export of items from the United States (including, but not limited to, commodities, software or technology) subject to the Export Administration Regulations, such items were exported from the United States by Seller in accordance with the Export Administration Regulations. Customer agrees that it will not divert, use, export or re-export such items contrary to United States law. Any diversion of an item contrary to US law is strictly prohibited. Customer expressly acknowledges and agrees that it will not export, re-export, or provide such item(s) to any entity or person within any country that is subject to United States economic sanctions within the control of the Office of Foreign Assets Control without obtaining prior authorization from the United States Government.

All products may be returned within 30 days of receipt of the item. Items that are returned within 15 days of receipt in unused condition shall be subject to a full refund. If the item is returned within days 16 through 30 or in used condition, there will be a 10% restocking fee deducted from the refund. All Final Sale merchandise cannot be returned. Other nonreturnable purchases include digital content, gift packaging, memberships, completed services, consumable items including 3D printer filament, and items returned that are damaged, unsanitary or missing major contents. We warrant the Gigabot against defects in materials and workmanship under ordinary use for 30 days from the date of receipt. This limited warranty applies only to hardware components of the Gigabot that are not subject to accident, misuse, neglect, fire or other external causes, unauthorized use, alterations, or repair, installation or enabling of unauthorized software or services, unauthorized alterations to the Gigabot or unauthorized resale. Any voltage usage outside of the manufacturer's offerings is not covered by warranty and re3D will not be liable for injury incurred by the user.

If we elect to do a replacement of your device, we will place the cost of the device (the then prevailing MSRP plus tax) hold on your credit card. We will charge the full retail price of the replacement device if we do not receive your original device within 21 days of delivering your new device.

Information has been carefully checked and is believed to be accurate; however, no responsibility is assumed for inaccuracies. Re3D reserves the right to make changes without further notice to any products to improve reliability, function, or design. Re3D does not assume any liability arising out of the application or use of any of its products; neither does it convey any license under its patent rights of others.